0

t

less waste rubber

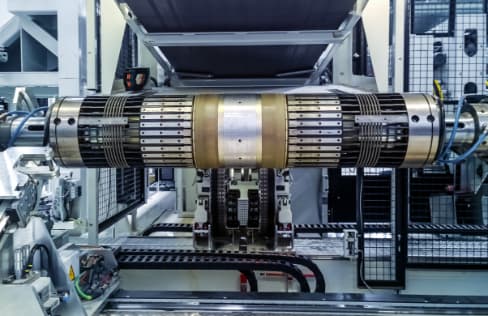

Spring Vents for Tire Manufacturing

Using spring vent technology in tire manufacturing is a minor decision with huge impact. Representing an option to forget the small but functionally important hairs on the tire surface, spring vents lead air out of the mould without leaving the undesired stubble behind. This keeps the tire surface flawless, smooth, better-looking, and better qualified for labelling.

Yet the biggest benefits are not aesthetic but environmental.

Tire trimming produces hundreds of tons of vulcanized waste that is difficult or impossible to recycle. That is a waste of both money and the environment.

If you cannot recycle it – avoid it.

Each tire trimming produces approximately 28 grams of waste rubber or more. That may sound little unless you calculate some more. Tire factories’ standard annual production rate is 10 million tires. Globally, with an annual production of 1,5 billion tires, using a method that prevents the rubber residue from forming means a huge annual saving in rubber consumption. In a more illustrative way, with this same amount of rubber residue, we could produce millions of new tires. Yet, unlike with some other materials, vulcanized rubber is a waste that cannot be recycled. It has to be avoided in the first place.

Benefits for tire manufacturing

Smoother processes

- Savings in cleaning

- Faster cooling

- Easier tire inspection on machine

- Easier labelling

- Unproblematic air trapping with

difficult compounds like silica

Better tire appearance

- Flawless

- Better-looking

- Smooth

Applicable to all moulds

- Steel, aluminium

- Cast or engraved

- Old or new